Equipment

We are equipped with:

- CNC-lathe machines with automatic bar loaders up to Ø 65 mm

- CNC-processing centres

- multi-spindle lathe machines with thread cutting and grinding facilities, hexagonal socket broaching facilities

- single spindle lathe machines

- automatic feed lathe machines, chuck diameter up to 160 mm

- turret lathe machines, max. diameter of 36 mm

- centreless universal grinding machine for continuous feed of 6 to 70 mm

- milling machines, second-operation lathes

- gang drilling machines with thread cutting

- off-centre presses, shears

- sandblasting facilities

- drilling and parting-off machines

- band-saw machines

Here you will find our complete machinery list.

Quality assurance is a permanent feature of our manufacturing.

To achieve this, the following criteria have been put in place:

- modern process-orientated quality management

- certification according to DIN ISO 9001:2015

- EU-Öko-Audit

- SPC Statistical Process Control

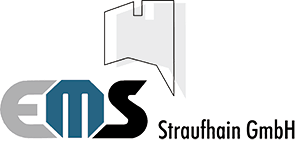

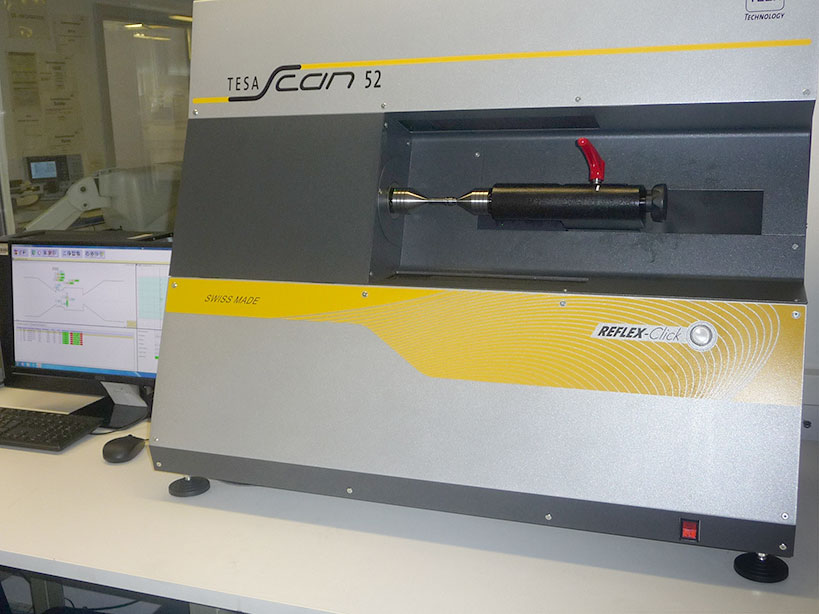

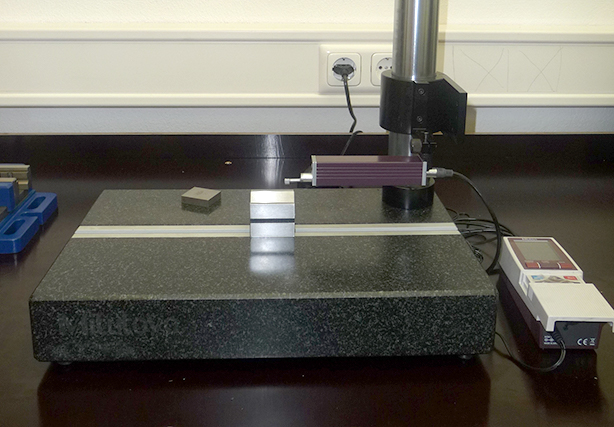

- electronic linear measurement technology

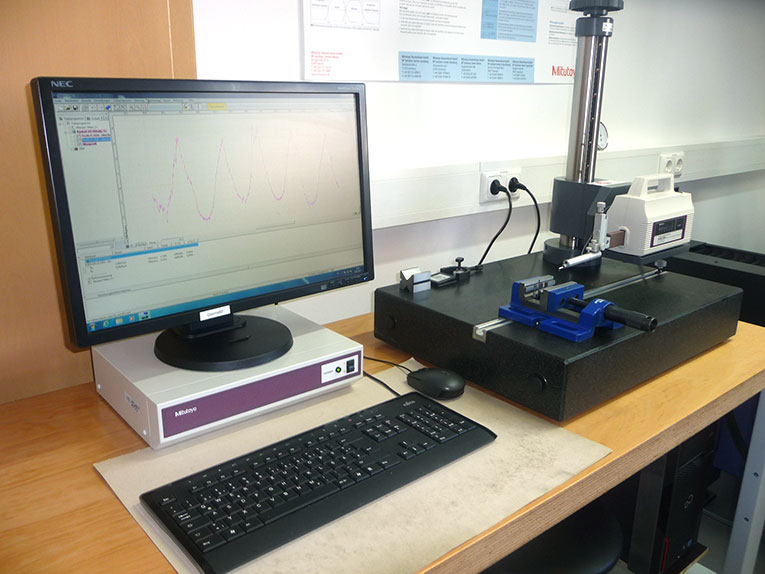

- optical tool and work-piece measuring

- measuring microscope

- background of more than 5,000 full apprenticeships

With the audits carried out by our customers, we were awarded exclusively ‘A’ grades!

High quality due to modern machinery

Production is supported by computers from start to finish. This enables us to fulfil extremely high quality requirements.

Our quality and environmental management system ensures our products are environmentally-friendly.

For demanding turning and milling work we offer a modern production plant and high quality measuring instruments.

Because of our technical equipment and the know-how of our qualified workforce, we are in the position to process a wide variety of materials.

- Afree-cutting steel

- carbon steel

- stainless steel

- aluminium

- brass

- plastic